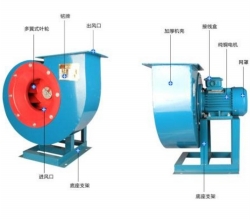

4-62 Series Centrifugal ventilator fan

Generality

Model 4-62 centrifugal ventilator is generally used to discharge ordinary dust, also can be used for general gas discharge or other suitable occasions such as factories, warehouses, air delivery system.

The F4-62 centrifugal fan is a derivative design of the original 4-62 centrifugal fan, and its air performance is completely the same as that of the 4-62 type fan. And simple packing seal. Housing and impeller is made of stainless steel 1 chromium 18 Ni 9 titanium), suitable for conveying general acid gas, gas temperature is not more than 50 ℃. The dust and hard particles in the gas are no more than 150 mg / m ~ (3).

The fan is made into two types of left-handed and right-handed respectively. The fan has six angles: 0 degrees 45 degrees, 90 degrees, 135 degrees, 180 degrees, and 225 degrees; It has four angles: 0 degrees 45 degrees, 90 degrees and 180 degrees.

Mounting test car

1. In order to avoid noise and occupy too much building area, the fan can be installed outside the main factory building, but must be installed indoors to prevent the motor from getting damp.

2. Determination of basic dimensions:

The foundation should be widened by 200 mm than the base of the machine.

(2) the foundation should be 150 ~ 200mm higher than the ground level, and the whole thickness of the foundation should be determined by the properties of the soil and the freezing depth. The masonry of the foundation should be built on the hard soil, the depth of which is not less than 0.5 m.

The foundation above the ground must be given cement and earthen red lead to prevent concrete from being damaged by lubricating oil materials.

4) the fan must be calibrated with horizontal dimension after placed on the foundation, and the gasket is allowed under the seat, but the cushion must be strong enough to prevent the base from contact with the foundation.

5) when connecting the inlet and outlet air pipe with the fan, the screw of the bottom foot of the fan should be fastened and then the screw of the inlet and outlet duct should be tightened. At the same time, the weight of the air pipe should be strictly prevented from being loaded into the fan, resulting in the deformation of the fan shell and the cause of collision.

3. There must be a comfortable position around the installation fan so as to facilitate the maintenance work in the future, its width should not be less than 1.5 m.

4. Inspection:

Focus on the correctness of each part of the installation, the connection part is firm.

Lubricating grease for bearing (bearing housing 2/3 is the most suitable).

3) the impeller and the inlet use the hand to move slowly, check for friction (if there is friction, check for correction.

4) the ventilation ducts and the airframe have left behind any sundries.

5) are the shields fitted.

( 6 ) Check whether the door check is flexible or not .

5. Test run:

Close the inlet valve and open the outlet valve slightly.

Power supply according to the regulations of motor brand.

Check that the steering of the motor is consistent with that of the blower, and then connect the screw of the coupling and the shield to avoid the deviation of the steering, resulting in loose nut on the shaft of the fan affecting the normal use of the fan.

Motor power supply should be based on voltmeters and ammeters to keep informed of motor load so as to avoid overload. If there is an overload of motor, it should be adjusted to the rated load to adjust the inlet and outlet air duct regulating door, so as to avoid accidents.

Check that the bearing temperature is normal and the temperature rise is not higher than 40 ℃.

Check ventilator for abnormal sound in operation, stop check immediately if there is metal erasure.

(7) ventilator initial test car for 24 hours to stop inspection of the various departments, such as no abnormal operation.

Causes and remedial measures of Fan overload

1. Large vibration: generally, the balance is not good or the balance has been destroyed, should be adjusted dynamic balance, or the inlet and outlet adjustment door is completely closed to cause vibration, so the outlet should be slightly open.

2, insufficient air volume: generally, the actual use of wind pressure is higher than the prescribed wind pressure, can be regulated by the import regulating door.

3 . The main shaft is deformed : it may be worn by the bearing , or the impeller may be subjected to strong vibration during rotation , and the bearing shall be disassembled and the main shaft shall be straightened .

Operation instruction

1. Starting

(1) a check before starting, the focus is whether the parts are tightened, or whether there are any sundries in the shell.

The inlet and outlet adjustment door is restored to the specified position (I. E. the inlet valve is closed, the outlet valve is slightly opened.

Whether the bearing grease is adequate.

2. Performance adjustment

Gradually open the adjusting door and adjust the outlet to the required level.

Pay attention to the load of motor when adjusting air volume.

maintenance and inspection

1. Maintenance

Pay attention to the lubricating grease inside the bearing.

Air pressure gauges shall be installed in the air inlet pipes.

The temperature of the medium should exceed 50 ℃, and there should be no viscous or rigid particulate matter.

4) all measuring appliances shall be fitted with indicator lights and protective covers.

2, check and repair:

Before each inspection must be carried out gradually, that is, external inspection, then internal removal inspection, but in principle the new machine should use 500 hours to replace the new bearing grease 100 hours inspection, once a year overhaul. In external repair, pay attention to the cleaning of all parts at any time, the impeller must always keep clean, because unclean rotor imbalance, affect service life, check impeller can first use hard brush to remove dust. Then examine carefully whether there is any unusual (that is, rivet shedding, blade cracking, etc.), the bearing is torn apart to see if it is worn and damaged, the spindle is bent, the impeller and bearing are removed and cleaned with kerosene, and the grease is replaced for one year.Overhaul once, should be part of the shell inspection.

1) whether the shell seal gasket does not work.

2) is the housing screw damaged,or not.

Model 4-62 centrifugal ventilator is generally used to discharge ordinary dust, also can be used for general gas discharge or other suitable occasions such as factories, warehouses, air delivery system.

The F4-62 centrifugal fan is a derivative design of the original 4-62 centrifugal fan, and its air performance is completely the same as that of the 4-62 type fan. And simple packing seal. Housing and impeller is made of stainless steel 1 chromium 18 Ni 9 titanium), suitable for conveying general acid gas, gas temperature is not more than 50 ℃. The dust and hard particles in the gas are no more than 150 mg / m ~ (3).

The fan is made into two types of left-handed and right-handed respectively. The fan has six angles: 0 degrees 45 degrees, 90 degrees, 135 degrees, 180 degrees, and 225 degrees; It has four angles: 0 degrees 45 degrees, 90 degrees and 180 degrees.

Mounting test car

1. In order to avoid noise and occupy too much building area, the fan can be installed outside the main factory building, but must be installed indoors to prevent the motor from getting damp.

2. Determination of basic dimensions:

The foundation should be widened by 200 mm than the base of the machine.

(2) the foundation should be 150 ~ 200mm higher than the ground level, and the whole thickness of the foundation should be determined by the properties of the soil and the freezing depth. The masonry of the foundation should be built on the hard soil, the depth of which is not less than 0.5 m.

The foundation above the ground must be given cement and earthen red lead to prevent concrete from being damaged by lubricating oil materials.

4) the fan must be calibrated with horizontal dimension after placed on the foundation, and the gasket is allowed under the seat, but the cushion must be strong enough to prevent the base from contact with the foundation.

5) when connecting the inlet and outlet air pipe with the fan, the screw of the bottom foot of the fan should be fastened and then the screw of the inlet and outlet duct should be tightened. At the same time, the weight of the air pipe should be strictly prevented from being loaded into the fan, resulting in the deformation of the fan shell and the cause of collision.

3. There must be a comfortable position around the installation fan so as to facilitate the maintenance work in the future, its width should not be less than 1.5 m.

4. Inspection:

Focus on the correctness of each part of the installation, the connection part is firm.

Lubricating grease for bearing (bearing housing 2/3 is the most suitable).

3) the impeller and the inlet use the hand to move slowly, check for friction (if there is friction, check for correction.

4) the ventilation ducts and the airframe have left behind any sundries.

5) are the shields fitted.

( 6 ) Check whether the door check is flexible or not .

5. Test run:

Close the inlet valve and open the outlet valve slightly.

Power supply according to the regulations of motor brand.

Check that the steering of the motor is consistent with that of the blower, and then connect the screw of the coupling and the shield to avoid the deviation of the steering, resulting in loose nut on the shaft of the fan affecting the normal use of the fan.

Motor power supply should be based on voltmeters and ammeters to keep informed of motor load so as to avoid overload. If there is an overload of motor, it should be adjusted to the rated load to adjust the inlet and outlet air duct regulating door, so as to avoid accidents.

Check that the bearing temperature is normal and the temperature rise is not higher than 40 ℃.

Check ventilator for abnormal sound in operation, stop check immediately if there is metal erasure.

(7) ventilator initial test car for 24 hours to stop inspection of the various departments, such as no abnormal operation.

Causes and remedial measures of Fan overload

1. Large vibration: generally, the balance is not good or the balance has been destroyed, should be adjusted dynamic balance, or the inlet and outlet adjustment door is completely closed to cause vibration, so the outlet should be slightly open.

2, insufficient air volume: generally, the actual use of wind pressure is higher than the prescribed wind pressure, can be regulated by the import regulating door.

3 . The main shaft is deformed : it may be worn by the bearing , or the impeller may be subjected to strong vibration during rotation , and the bearing shall be disassembled and the main shaft shall be straightened .

Operation instruction

1. Starting

(1) a check before starting, the focus is whether the parts are tightened, or whether there are any sundries in the shell.

The inlet and outlet adjustment door is restored to the specified position (I. E. the inlet valve is closed, the outlet valve is slightly opened.

Whether the bearing grease is adequate.

2. Performance adjustment

Gradually open the adjusting door and adjust the outlet to the required level.

Pay attention to the load of motor when adjusting air volume.

maintenance and inspection

1. Maintenance

Pay attention to the lubricating grease inside the bearing.

Air pressure gauges shall be installed in the air inlet pipes.

The temperature of the medium should exceed 50 ℃, and there should be no viscous or rigid particulate matter.

4) all measuring appliances shall be fitted with indicator lights and protective covers.

2, check and repair:

Before each inspection must be carried out gradually, that is, external inspection, then internal removal inspection, but in principle the new machine should use 500 hours to replace the new bearing grease 100 hours inspection, once a year overhaul. In external repair, pay attention to the cleaning of all parts at any time, the impeller must always keep clean, because unclean rotor imbalance, affect service life, check impeller can first use hard brush to remove dust. Then examine carefully whether there is any unusual (that is, rivet shedding, blade cracking, etc.), the bearing is torn apart to see if it is worn and damaged, the spindle is bent, the impeller and bearing are removed and cleaned with kerosene, and the grease is replaced for one year.Overhaul once, should be part of the shell inspection.

1) whether the shell seal gasket does not work.

2) is the housing screw damaged,or not.

Please contact us and get detailed Technical parameters and Drawings.

We could Design and Produce the Marine fan,Industrial Fan,and Other Ventilation Equipment according to your detailed requirement !- Previous Product:4-70 Series Industrial Centrifugal fan

- Next Product:4-75-11 Series Industrial centrifugal fan